General Al Cano Tile (M-bar)

- >

- Products

- >

- General Al Cano Tile (M-bar)

General Al Cano Tile (M-bar)

AL TILE system which is most commonly used among metallic finishing materials for ceilings indoors/outdoors of building architecture adopted CLIP-IN fixing method. Accordingly at the time of using it at external canopy and pilotti fear for its falling off is high. It had problem of falling off when wind was very strong actually. Canotile system being developed by Yoochang adopted screw fixing method thus its sturdiness was improved and wind-pressure resistance was secured. It also can secure beautiful external appearance by using 15 mm or 20 mm joint line.

- Product outline

- Product drawing

- Information for construction

- Miscellaneous

General description of AL CANO TILE (M-BAR)

AL TILE system which is most commonly used among metallic finishing materials for ceilings indoors/outdoors of building architecture adopted CLIP-IN fixing method. Accordingly at the time of using it at external canopy and pilotti fear for its falling off is high. It had problem of falling off when wind was very strong actually. Canotile system being developed by Yoochang adopted screw fixing method thus its sturdiness was improved and wind-pressure resistance was secured. It also can secure beautiful external appearance by using 15 mm or 20 mm joint line.

General description of AL CANO TITLE (M-BAR)

(1) Material

- KSD 3506 (melt galvanized steel plate)

KSD 3609 (Steel material support member for construction)

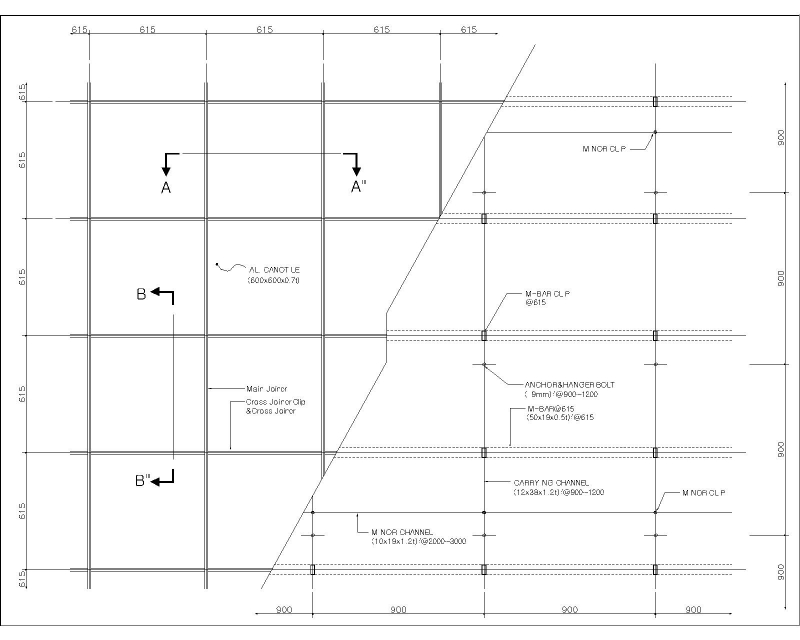

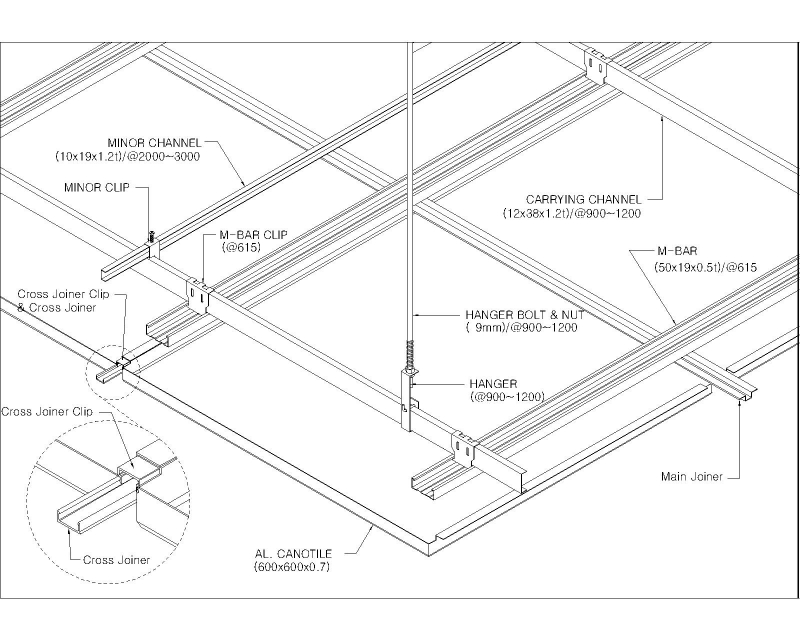

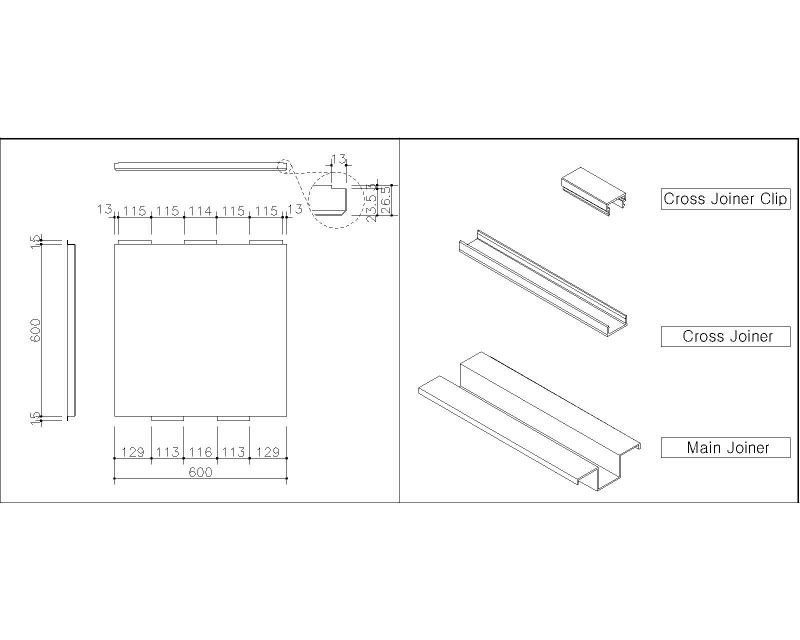

(2) Dimension

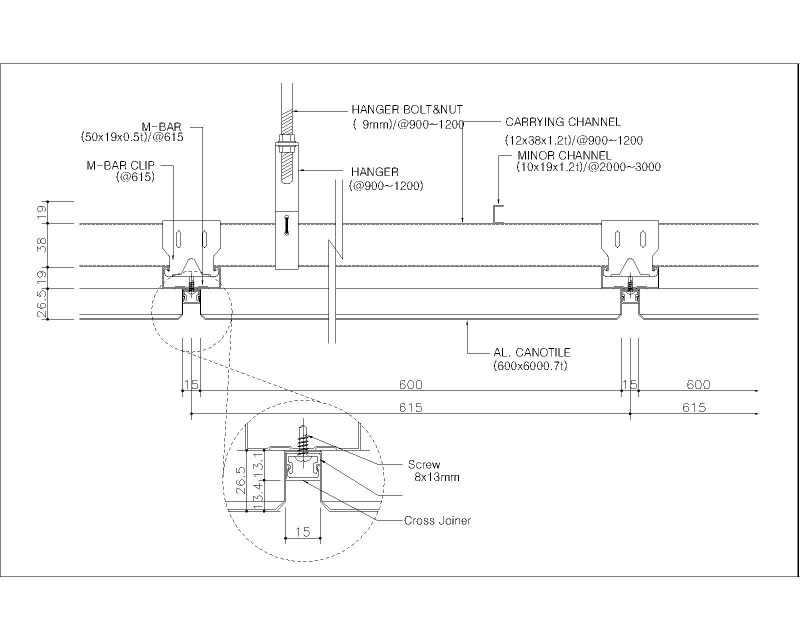

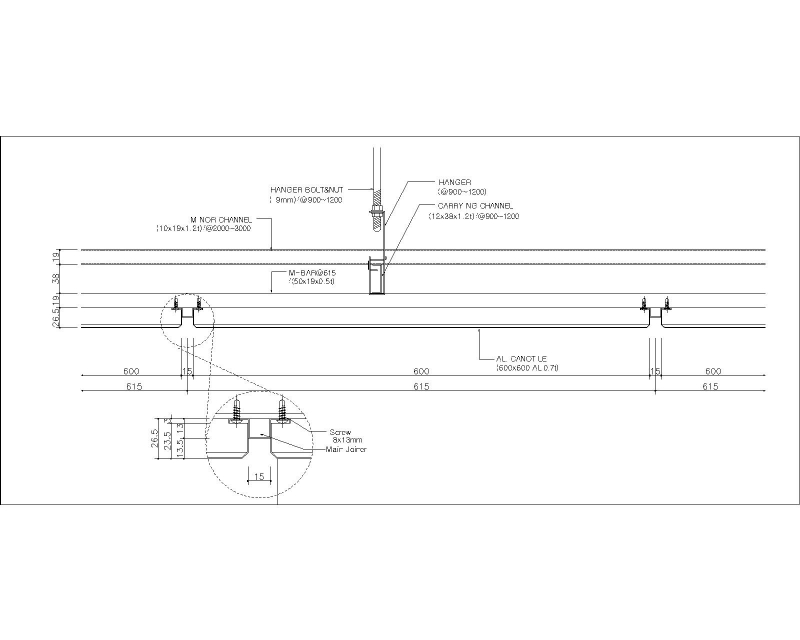

- ① M-BAR : 50mm X 19mm X 0.5T

- ② HANGER BOLT : ψ9mm

- ③ HANGER & PIN : 100mm X 20mm X 2.0T

- ④ HANGER NUT : ψ9mm

- ⑤ CARRYING CHANNEL : 38mm X 12mm X 1.2T

- ⑥ C/C JOINT : 100mm X 35mm X 10mm X 1.0T

- ⑦ MINOR CHANNEL : 19mm X 10mm X 1.2T

- ⑧ M/C CLIP : 38mm X 23mm X 14mm X 1.2T

- ⑨ M-BAR CLIP : 38mm X 47mm X 0.5T

- ⑩ M-BAR JOINT : 85mm x 47mm x 0.5T

- ⑪ Al main joiner: width=20 mm, 15 mm, L=3,000

- ⑫ Al cross joiner & clip: width=20mm, 15mm, L=600

- ⑬ Cano-tile: 600 x 600 x 0.7T or above

- ⑭ MOLDING : 15X30X1.0T

Special feature of general AL CANO TILE (M-BAR)

- * Sturdiness: By fixing with piece there is little fear for falling off.

- * Beautiful exterior: It is concealed type and bar is not visible.

- * Safety: sturdy and distortion free ceiling

- * Incombustibility: steel material structure using galvanized steel plate

- * Function for adjustment of level: possible for perfect level

(1) Setting up centerline of building: After accurate measurement of ceiling surface set up centerline after checking other work schedule such as lightline and position of diffuser etc.

(2) Strong anchor work

- ① At the time of strong anchor work when centerline is set up mark part for fixing strong anchor (Ф9mm) at slab surface and punch hole with drill and fix it.

- ② At the time of work for cash iron insert (Ф9 mm) install it at form according to drawing.

- ③ Caution: Pay attention to intervals between anchor and insert and right angle.

- ④ It is ideal to make interval for installation as @900∼ 1,200 mm for strong anchor or insert in consideration of direction of installation of carrying channel.

(3) Molding line level check

- ① Use of water level or level

- a. Confirming position by means of drawing (confirming height of ceiling)

- b. Confirming the position by water level and ink pot string marking between positions.

- ② Caution: At the time of using water check make sure to check level after checking any presence of air bubble in hose and breaking of hose.

(4) Attachment of wall molding (using after painting angle or sea gull molding)

- ① Attach molding along the India ink line and fix wall molding by using 1" concrete nail.(interval: 500∼1,000 mm)

- ② Be careful not to slacken the height and interval between moldings.

- ③ In connection with facilities such as curtain box it shall be attached according to specification.

(5) Installation of hanger bolt

- ① Upper part of hanger bolt is fixed to strong anchor or insert and lower part of bolt is fixed hanger and nut in consideration of ceiling height.

- ② At the place where installation duct or other obstacles are work shall be carried out after reinforcement according to drawing and specification.

(6) Installation of lightline

- Install lightline according to specification but it is required to have consultation with persons in charge of electricity and facility.

(7) Installation of carrying channel

- After tying hanger set and carrying channel and fix them. Install it at an interval of @900∼1,200 mm. Connect the connecting part of carrying channel by means of carrying joint.

- And make sure to install carrying channel not to be off from box face by more than 30 cm.

(8) Installation of MINOR Channel

- When area of work is broad reinforce and fix above the installed carrying channel with reinforcing channel (minor channel) and install it at an interval of 2,000 ∼3,000 mm.

(9) Installation of M- BAR

- ① After placing string at centerline of the work then install sturdily the M-BAR by using WIRE CLIP by matching it to lightline and in a right angle direction toward carrying channel.

- ② Intervals of installation of M-BAR shall comply with drawing and specification. Provided that, when it is not indicated on drawing or specification it shall be installed at interval of 300 mm.

- ③ M-BAR is mounted on wall molding or curtain box wing part and fixed.

- ④ Level of installed ceiling shall be accurately set by water level or level device and by using hanger bolt and nut.

(10) Installation of Cano-tile

- ① Before installation of Cano-tile make main joinder cross lower part of SQ-bar in right angle and fix it.

- ② According to interval of main joinder attach Cano-tile to lower part of SQ-bar and attach Cross joiner clip and fix it with piece then finish work by inserting cross joiner.

- ③ Form of Cano-tile shall comply with drawing.

(11) Installation of curtain box

- ① Manufacturing and installing products suitable to use according to specification (separate painting)

- ② Welding work is carried out concurrently therefore install work bench to enable safety in work and working in comfortable stance.

(1) Handling and storage of the product

- ① It shall be stored at a condition of relative humidity of 80% or less.

- ② To prevent any damage from water or moisture always keep it at dry and clean place.

- ③ Be careful not to damage corners

- ④ Maintain certain space from the wall surface and place spread sheet and then lay down water-proof sheet then preserve it.

(2) Environmental condition at the time of carrying out the works

- ① At the time of works temperature of 30℃ or less and relative humidity of 80% or less shall be maintained.

- ② The works shall be commenced after completion of joiners' works.

- ③ Before. during and after the works air-conditioners shall be operated so that proper level of indoors temperature and relative humidity are maintained.

- ④ The works shall be commenced after completion of all the papering and painting walls and ceiling.

(3) Caution at the time of carrying out works

- Pipe-layng and electric works shall be completed before installation of M-bar and then works shall be carried out.

(4) Conditions for carrying out works

- ① The contractor for the works shall consult with the client with sufficient consideration of site conditions.

- ② While carrying out works at the time of appearance of any problems works shall be continued after sufficient consultation with the client.

- ③ As much as possible ceiling plan intended by the designer shall be observed.