Products

Yoochangs's Challange is ongoing

FOR A BETTER SPACE

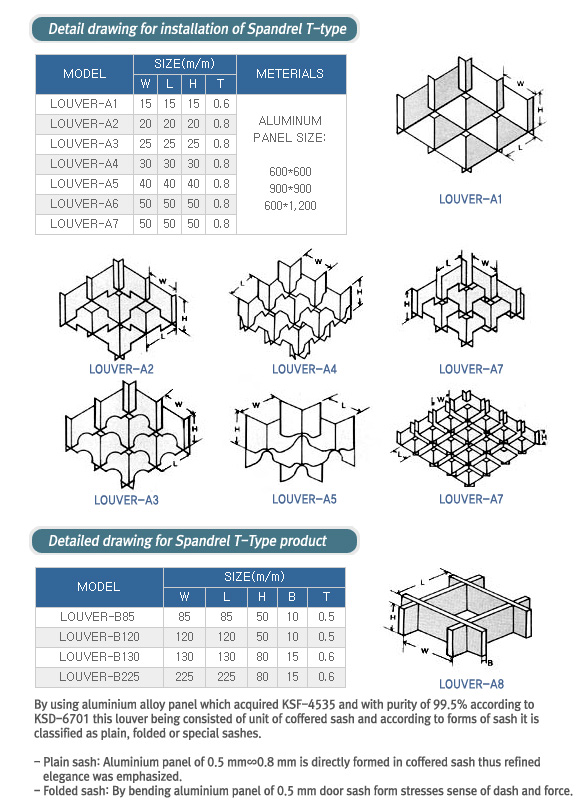

AL LOUVER (double sash, 50 angle, 75 angle, 85 angle, 100 angle, 120 angle, 150 angle)

Al Louver system is a system emphasizing openness of indoors and expansiveness of floor height through open cellular ceiling of module. It is a system which applies to sale facilities and public places and sector requiring indirect illumination.

General description of A-Louver 75 angle

(1) Definition of terms

- System: Louver system

(2) Transportation and handling:

- ① Transportation: Types and names: Record type, name, dimension and manufacturing date etc. on label and pack and transport.

- ② Handling: Handle it according to instruction from manufacturer and requirement of users.

Product of Al-Louver 15 angle

(1) Material

- KSD 7081 (colored metallic ceiling material for construction)

KSD 3609 (Steel material support member for construction)

(2) Dimension

- ① ㅂ-BAR ; 42mm X 10mm x 1.2T

- ② HANGER BOLT : ψ9mm

- ③ HANGER (ㅂ-BAR용)

- ④ HANGER NUT : ψ9mm

- ⑤ ㅂ-BAR JOINT

- ⑥ MOLDING

- ⑦ Louver: For size see design drawing.

(75mm x 75 mm x 50 mm x 10 mm x 0.5T)

Special feature of Al-Louver 15 angle

- * Through indirect illumination it creates subdued mood.

- * It makes massive structure look simple.

- * It emphasizes expansiveness of floor height.

- * It is suitable to subway and department stores because it controls noise.

(1) Setting up centerline of building: After accurate measurement of ceiling surface set up centerline after checking other work schedule such as lightline and position of diffuser etc.

(2) Strong anchor work

- ① At the time of strong anchor work when centerline is set up mark part for fixing strong anchor (Ф9mm) at slab surface and punch hole with drill and fix it.

- ② At the time of work for cash iron insert (Ф9 mm) install it at form according to drawing.

- ③ Caution: Pay attention to intervals between anchor and insert and right angle.

- ④ It is ideal to make interval for installation as @900∼ 1,200 mm for strong anchor or insert in consideration of direction of installation of '?'-Bar.

(3) Molding line level check

- ① Use of water level or level

- a. Confirming position by means of drawing (confirming height of ceiling)

- b. Confirming the position by water level and ink pot string marking between positions.

- ② Caution: At the time of using water check make sure to check level after checking any presence of air bubble in hose and breaking of hose.

(4) Attachment of wall molding (attach after painting molding in desired color)

- ① Attach molding along the India ink line and fix wall molding by using 1" concrete nail. (interval: 500∼1,000 mm)

- ② Be careful not to slacken the height and interval between moldings.

- ③ Attach it in consideration of facilities such as curtain box etc. according to specification.

(5) Installation of hanger bolt

- ① Upper part of hanger bolt is fixed to strong anchor or insert and lower part of bolt is fixed hanger and nut in consideration of ceiling height.

- ② At the place where installation duct or other obstacles are work shall be carried out after reinforcement according to drawing and specification.

(6) Installation of lightline

- Install lightline according to specification but it is required to have consultation with persons in charge of electricity and facility.

(7) Installation of '?'-Bar

- ① Install it by using hanger for '?' Bar according to dimension and by matching it to lightline after marking the centerline of the work.

- ② Interval of '?' Bar shall be set to be straight line according to drawing and specification.

- ③ '?' Bar is mounted on wall molding or wing of curtain box and fixed.

(8) Installation of Louver

- ① Level of installed ceiling frame is fixed accurately with hanger bolt or nut by using water level or level device.

- ② When louver is inserted into '?' bar then installation is finished.

- ③ Prohibit use of damaged finishing panel with scratch or panel which is dirty and its corner broken.

(9) Installation of curtain box

- ① Manufacturing and installing products suitable to use according to specification (separate painting)

- ② Welding work is carried out concurrently therefore install work bench to enable safety in work and working in comfortable stance.